Safety Culture Meetings

At BDS, our safety culture meetings cover a wide range of crucial topics, including:

- Forklift safety and OSHA housekeeping

- Fire safety and electrical safety

- Hearing protection and personal protective equipment

- Preventing slips and falls, as well as back injury prevention

- Accident/incident reporting and emergency response procedures

- Effective Communication Strategies – Prevention of violence in the workplace

Through these comprehensive discussions, we ensure that every team member is equipped with the knowledge and understanding necessary to maintain a safe and secure work environment.

Warehouse Safety Program

Overall Safety

We truly care about the well-being of our employees and emphasize personal safety, both inside and outside of the workplace. That’s why we strongly encourage our team members to wear their seat belts whenever they leave work and not to text while driving. We want everyone to make it home ALIVE!

At Bennett, safety isn’t just a policy; it’s ingrained in our culture, guiding how we live and work each day. Safety is Priority One.

Housekeeping

An often overlooked aspect of safety is maintaining effective housekeeping processes.

That’s why at BDS we prioritize this essential element by ensuring that:

- Aisles and floors are clear from any objects or materials that may obstruct the path.

- Materials are stacked and stored properly to prevent hazards.

- Any protruding nails, fasteners, or loosely secured items are promptly addressed.

- Large equipment is stored safely when not in use to prevent collisions or damage.

- Trash and debris that could lead to trips or slips are promptly removed.

- Spills of water, oil, or other liquids are promptly cleaned up from the floor.

By focusing on these housekeeping practices, we create a safer and more organized environment for everyone in the warehouse.

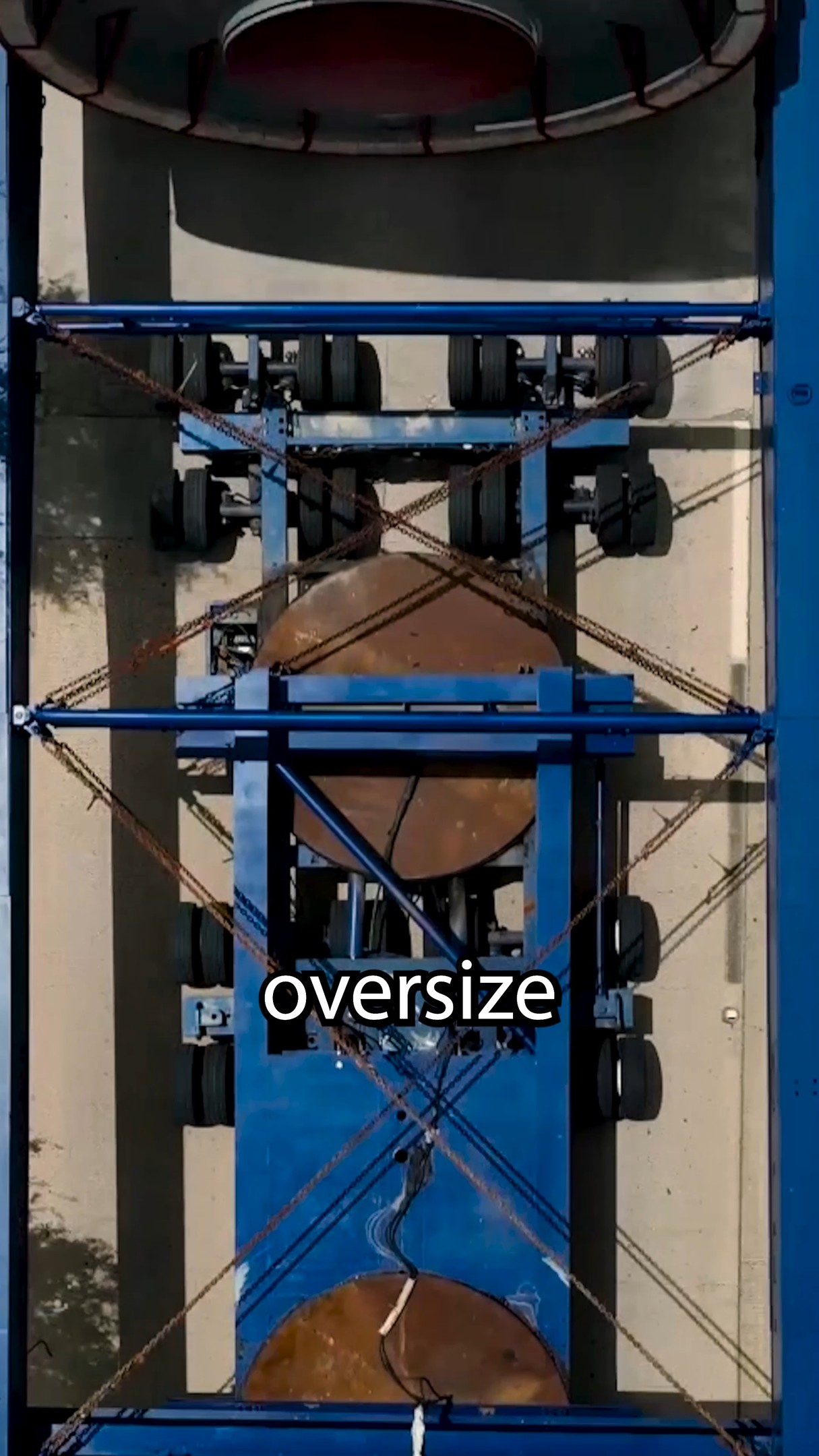

Material Handling

With material handling, vigilance is key, regardless of whether you’re using equipment or manually lifting and carrying items. At BDS, we prioritize the safety of our staff by providing comprehensive training and clear guidelines.

When operating a forklift, it’s crucial to adhere to the following guidelines:

- No one but the operator should ever ride on a forklift

- Never stand or walk under the raised part of a forklift, even if it’s empty

- Place forklift loads carefully so they’re stable and won’t fall off or tip the truck

- Drive a forklift slowly

- Keep forks – and loads – low and tilted back while moving

- Park a forklift with forks lowered and tilted flat, brake set, and key removed

By diligently following these safety measures, we create a secure environment, reducing the risk of accidents and ensuring the well-being of our team members.

Loading Dock Safety

To maintain a safe loading dock area, we rely on a combination of built-in protections and common sense.

Our warehouse operations team takes the following precautions:

- Checks dock plate load capacity before piling up materials or unloading.

- Slides the dock into place, rather than dropping it.

- Pays attention to weather impacting the loading dock area. To prevent slips and falls, we keep the area dry and prevent ice formation.

By adhering to these practices, we minimize risks for everyone involved in loading and unloading operations.

Join Our Community

Bennett Newsletter Subscription

Sign up to stay current with Bennett and Transportation Industry news. We send out a digital newsletter monthly. Unsubscribe any time.